Premiere at DREMA: Such a brush machine has not been on the market yet!

During this year's DREMA, for the first time on the Polish market, PolishStyl's newest solution - the PS series brush machine - will be presented.

- Everyone wants to get younger, but we like to make things older, especially wood! - says Boguslaw Szkutnik, president of PolishStyl, standing next to the company's latest solution, which is the PS series brushing machine. - Wood brushing, or wood structuring, is a very fashionable trend in furniture making, floor production, and even finishing house facades. Unfortunately, in many manufacturing companies this process is still done manually. And this makes it tedious, inaccurate and time-consuming. Our new series of PS brushers is designed to make this process easier and more mechanized.

Uniqueness of design

First of all, PS brushing machines allow not only structuring, but also grinding of parts, which contributes to the uniqueness and versatility of application of these machines!

Secondly, PolishStyl is one of the few manufacturers to supply both the machines and - produced at the plant in Nowa Dêba - the brushes. This makes it possible to perfectly match the entire technology in woodworking factories with very different capacity levels.

Thirdly, PS machines have a very robust frame design that prevents any vibration during the sanding/structuring processes, allowing precise work results. And only such will ensure that the desired brushing effect is achieved and give the parts the most perfect finish!

In two series and in two working widths

PS brushing machines are offered in two versions. Basic - Basic and expanded - Luxury. What are the differences?

The Luxury version has an electronic control panel, speed control and spindle direction change as standard. The electronic control panel allows precise control of the height setting and rotation of the spindles, as well as the speed of the conveyor belt. Both heads have bidirectional rotation.

In addition, the machines (both Basic and Luxury series) come in two working widths of the conveyor belt: 400 mm (PS-400 model) and 600 mm (PS-600 model). However, the width of the workpieces to be processed can be much wider.

Because the open design of the machine allows processing workpieces with a maximum width of 800 mm (for the smaller option) and 1,200 mm (for the larger option). In turn, the working height of the aggregates allows processing workpieces with a maximum height of as much as 310 mm.

In turn, two guide rollers hold the workpieces at the desired width of the conveyor. This makes it possible to grind or structure narrow surfaces!

Structuring and grinding

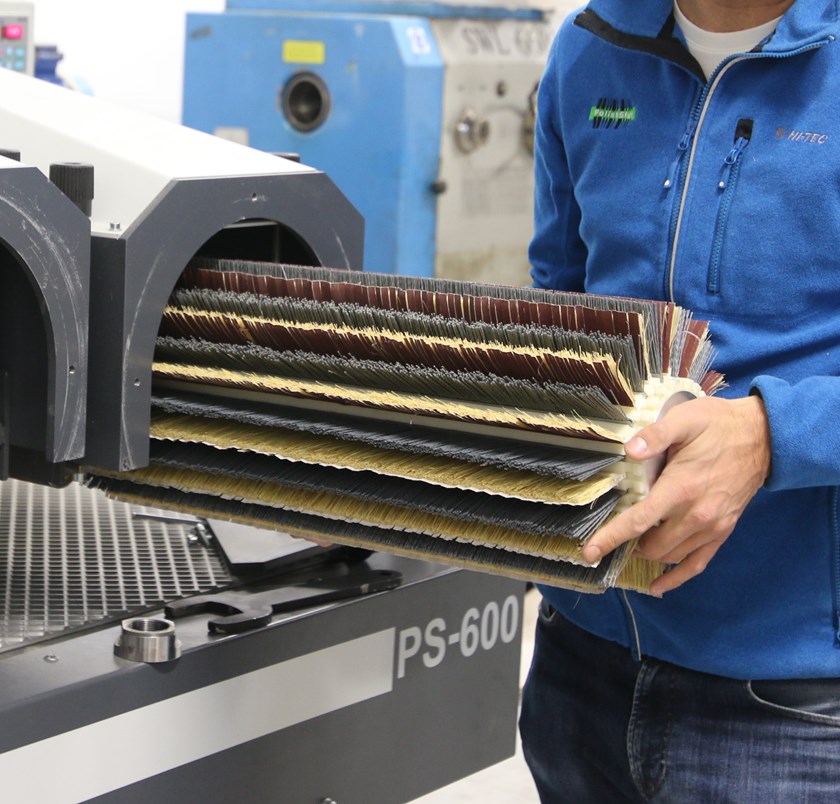

PS series brushing machines have 2 units that can be used for both structuring and grinding processes. How is this possible?

Each unit can be armed with brushes for grinding (with replaceable grinding cartridges) or structuring (steel and Tynex brushes). Their type is selected by PolishStyl experts according to the type of process and the work effect the customer wants to achieve.

As a manufacturer of heads and brushes, PolishStyl offers the widest spectrum and professional advice on their selection.

Premiere at DREMA 2024

Showing the PS brush machine at DREMA 2024 in Poznan will be the debut of this series of machines on the Polish market. Therefore, we invite you to visit our booth. PolishStyl consultants will present the operation of the brushing machine, help in the selection of technology as well as provide expert knowledge on brushing, sanding and wood structuring - informs the president of PolishStyl.

About PolishStyl

PolishStyl was established in January 2008. It is one of the more prominent suppliers of abrasives in Poland and abroad. It has won the trust of a wide range of customers - from small and medium-sized plants to the largest factories in the world. It was the first Polish manufacturer to introduce abrasive brush technology to the domestic market.

PolishStyl's advantage is its educated, experienced staff, with extensive knowledge in surface treatment of wood, varnish coatings, metals, glass, plastics and other materials. It provides all current and future customers with professional technical advice and support at every stage of cooperation.